Eddy Current and Ultrasonic NDE

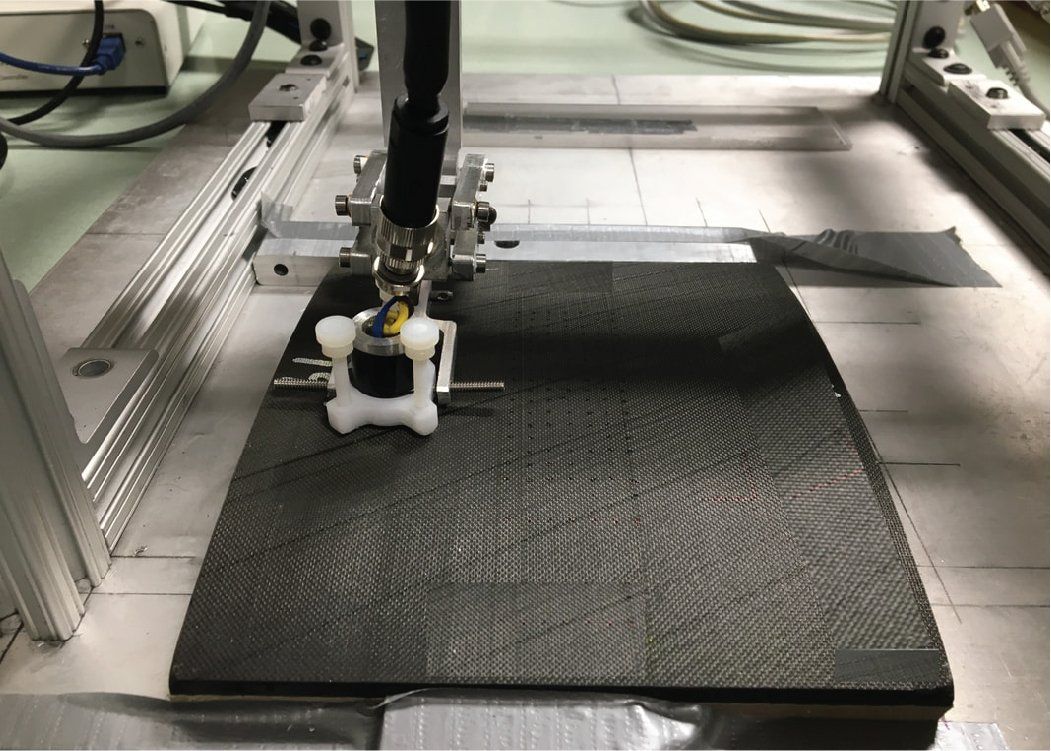

Box Elder Innovations designs and builds ultrasonic and/or eddy current nondestructive evaluation (NDE) systems for a variety of material applications including composite materials, metals, ceramics, particulate filled polymeric materials, and other complex material systems of interest to our customers. For materials containing electrically conductive components such as carbon fiber reinforced plastic, combining ultrasonics and eddy current provides a complementary system for a more complete characterization of these materials.

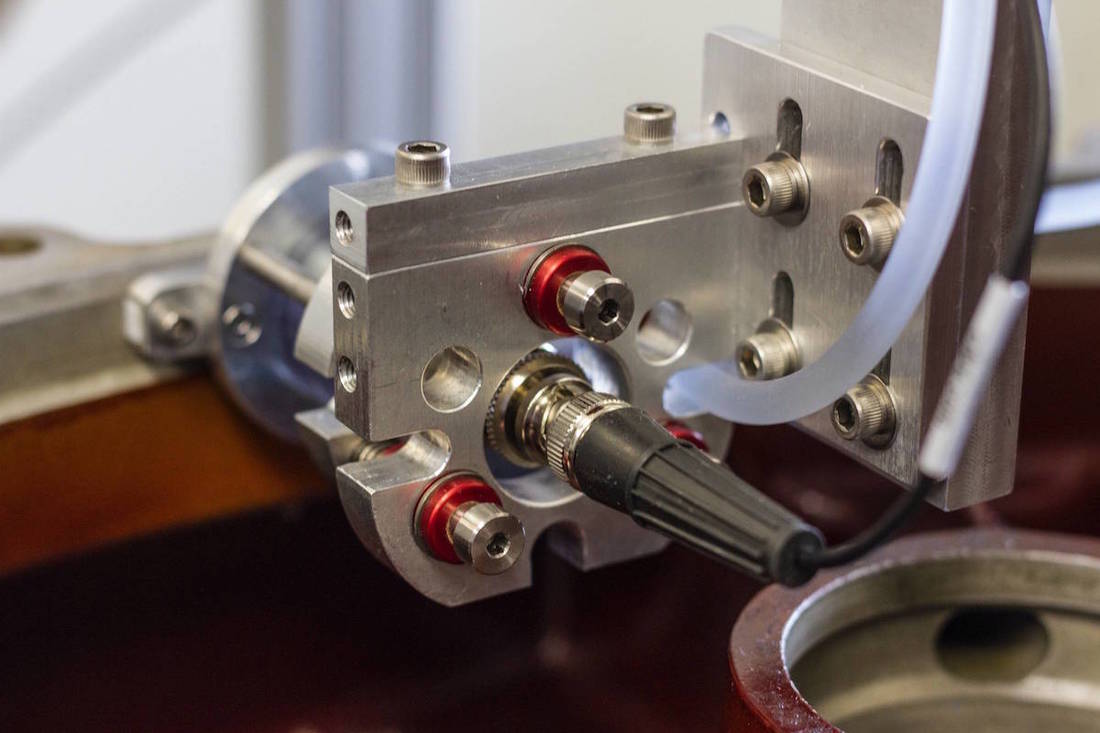

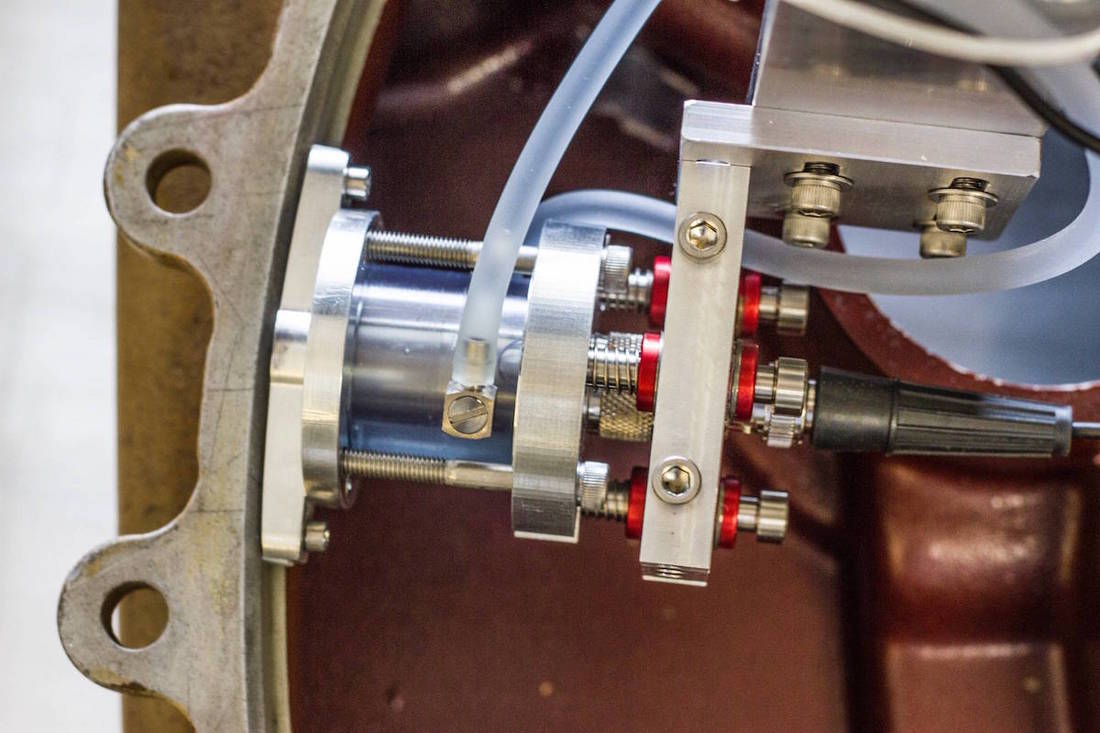

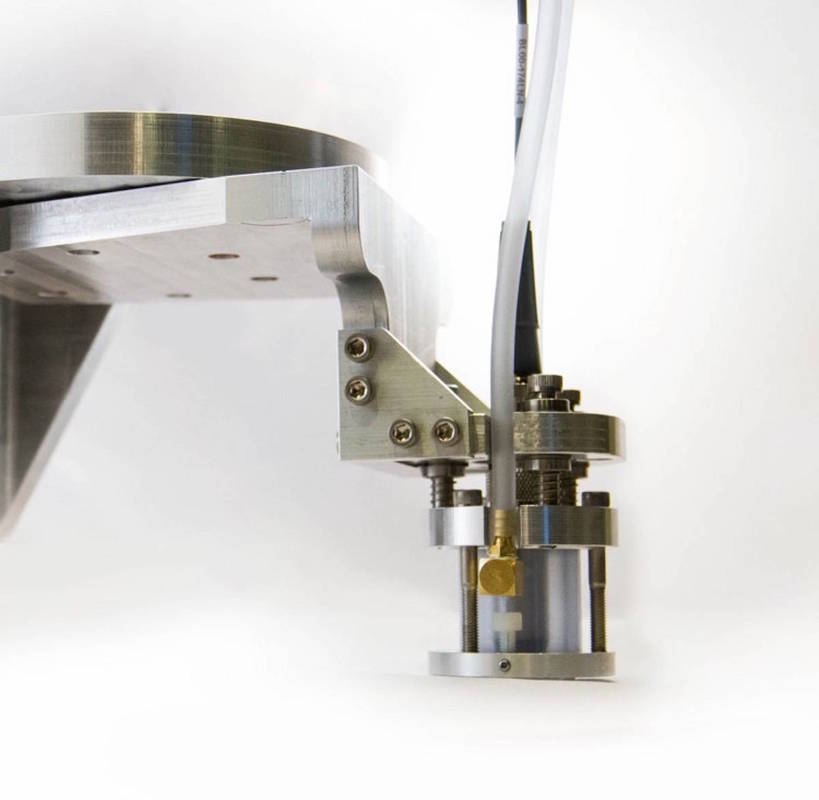

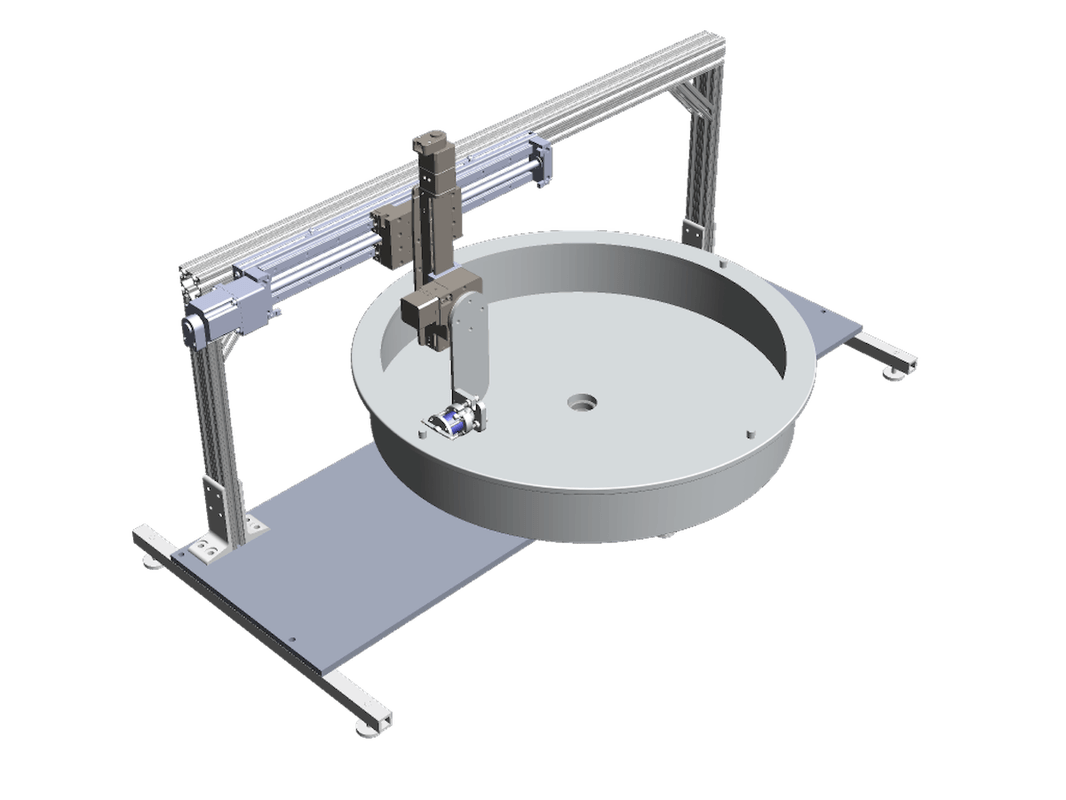

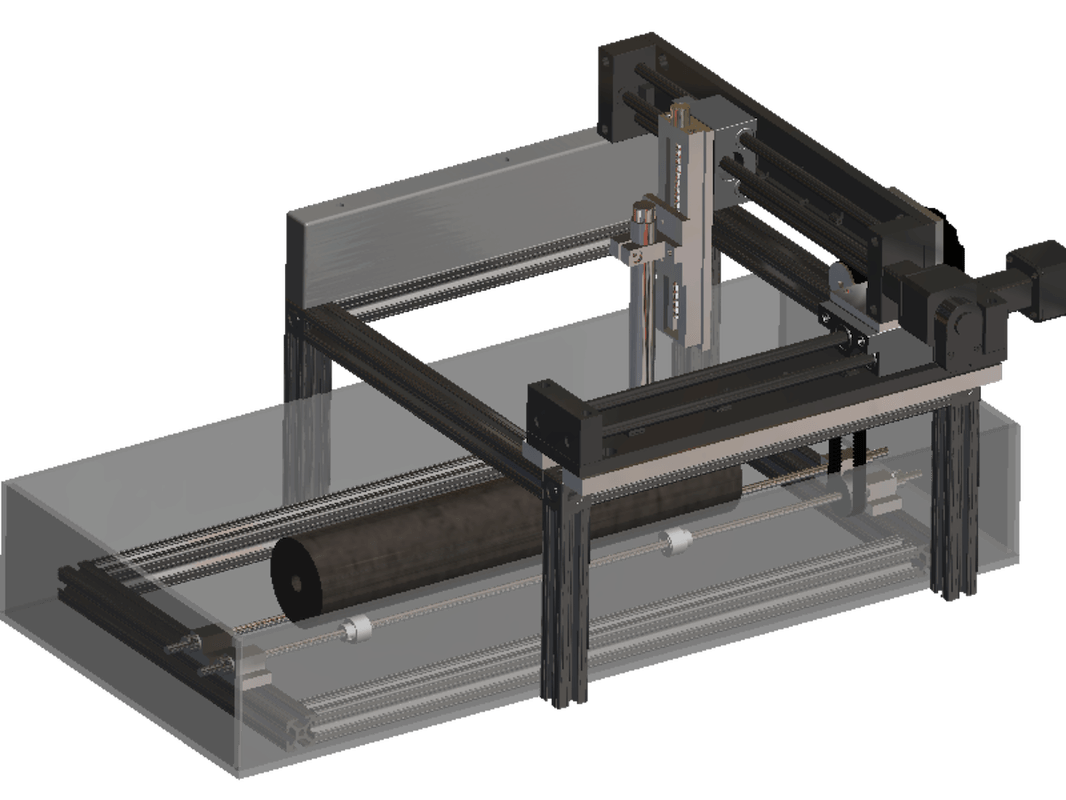

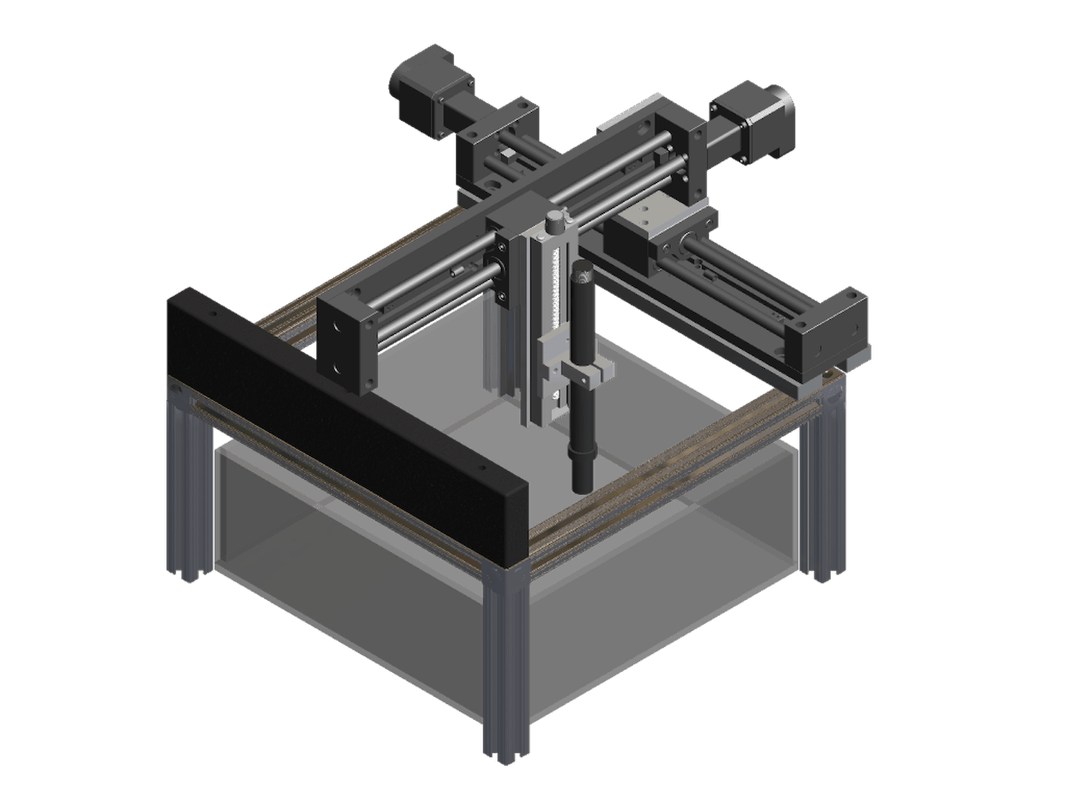

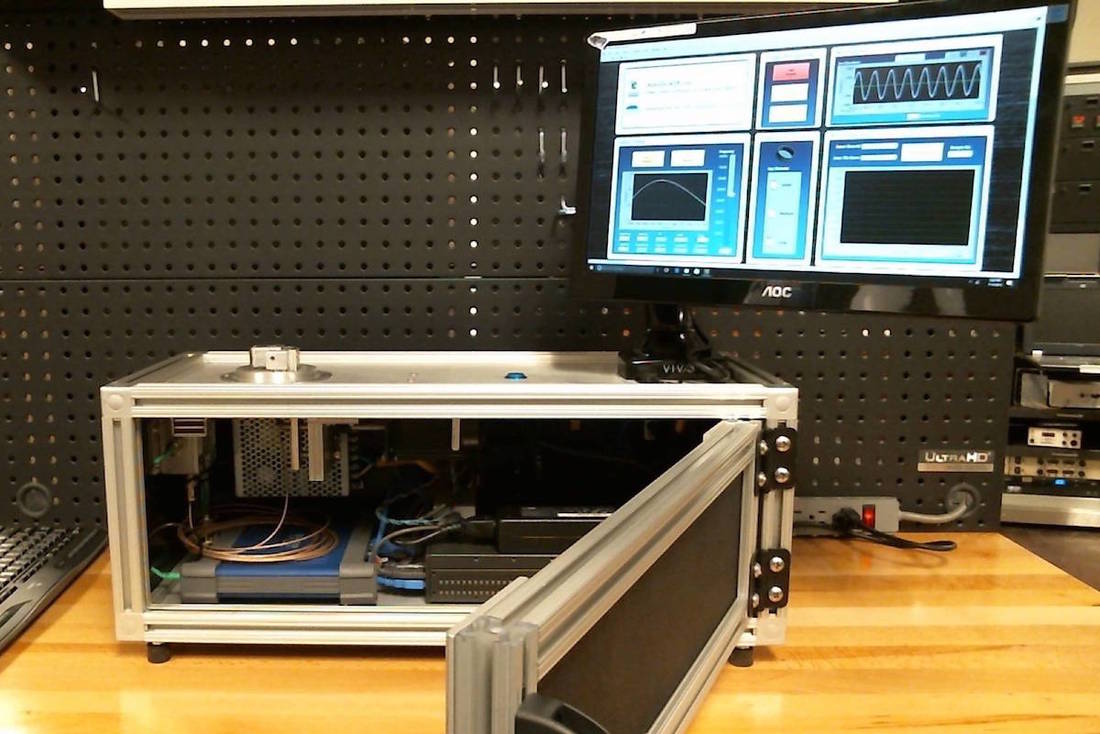

We provide motion control systems, data acquisition hardware, signal generation and conditioning, custom eddy current probes, and system software. Our software includes advanced signal processing and data analysis tools. We also can work with you to develop custom inspection methods, so the product is sure to fit your needs.

Nondestructive testing provides many potential benefits, such as:

- material characterization for manufacturing defects, impact damage, and material properties including measurement of elastic properties and fiber direction in composite materials

- locating and identifying types of defects

- measuring and tracking of material properties using statistical process control (SPC) practices for providing a history of product quality

- supporting failure investigations

- supporting development and verification of materials and processes for product quality verification and process reliability

- complementary use of ultrasonics and eddy current for a more complete characterization of defects and damage in carbon fiber composite materials

Interested in purchasing a standard system? Check out our FusionScan NDE System.

Our NDE products include both ultrasonic and eddy current systems designed for metal and composite material applications such as, filament wound composites, composites built with fiber placement technologies, chopped fiber and particulate filled composites, injection molded composites, metal matrix composites, and particulate filled rubber polymeric-based composites; and metals where microstructure, mechanical properties, residual stress, cracks, and other defects are of interest or concern. An ultrasonic test fixture is offered for coupling ultrasonic waves into materials where excessive coupling liquid is not desirable, or where coupling liquids such as alcohol are required. We offer both specific NDE system models and custom products tailored for your needs.